Building Materials for Commercial Construction Projects

Walco specializes in architectural elements for commercial exteriors. Our line of products includes skylights, facades, and roof systems that combine function and visual appeal.

What We Help With

Learn more about the kinds of products we source and how they fit into your next project.

Skylights

Increase natural light with options designed to fit a range of rooftops.

.png)

Architectural Facades

Create an exterior that’s attractive, safe, and cost-effective.

Roofing Systems and Recovering

Rely on roofing products that protect your building and more.

Skylights

Walco is a trusted nationwide distributor of skylights for commercial building projects. Due to this fact, we’re a champion of what these elements can do for your commercial property.

There are a number of benefits to increasing the amount of natural light that reaches the interior of your building. Perhaps the most apparent is increased energy efficiency from cutting down on artificial light. For this reason, skylights are a great way to decrease your energy bill and your carbon footprint.

The benefits don’t stop there. Natural light also creates a more attractive indoor environment for building occupants. Scientists at the Lighting Research Center have linked it to health benefits like lower stress levels and increased alertness. Skylights are the best way to capitalize on this incredible resource in your building.

Skylight Product Descriptions

Be sure to choose the right skylight for your next building project. We offer structural and architectural skylight options.

Skylights are the simplest and most effective tool to attain the benefits of daylighting in your commercial property. Our line of architectural skylights offers a modular option that can fit into almost any project. These adaptable designs can complement other architectural elements with ease.

The smaller dimensions of architectural skylights make them perfect for arranging in patterns and formations, giving you maximum flexibility in distribution of interior natural light. Available designs come in a range of shapes and sizes suitable for corridors, corners, and more, at an average size of 2x4 feet.

They also come in a ready-made, easy-to-install capacity that saves you time and money on your commercial projects.

For a simple and effective tool to maximize the comfort and energy efficiency of any building, architectural skylights are a great choice. This adjustable option gives you flexibility without excessive labor costs.

Larger, custom-sized structural skylights can enhance the appeal of entryways and other high-use areas with dazzling effects. The customizable nature of these skylights makes them perfect for the centerpiece of your commercial design. Whatever you’re envisioning, let the experts at Walco assist you in creating the perfect skylight.

At an average size of around 10x25 feet, structural skylights are a more integral part of the designs they appear in, often anchoring large or central spaces. There are larger design and construction costs associated with these skylights, but they make up for it in many ways.

Glazing options are available to cut the undesirable effects of heating and glare associated with other skylights. Low emissivity glazing drastically cuts the amount of infrared and UV radiation that would otherwise pass through your skylights, while high performance options like insulated and photovoltaic glasses offer even greater potential for energy savings.

Consider incorporating an impressive and energy-saving structural skylight into your next building project. We work with you to design and implement the custom solution that will elevate your design.

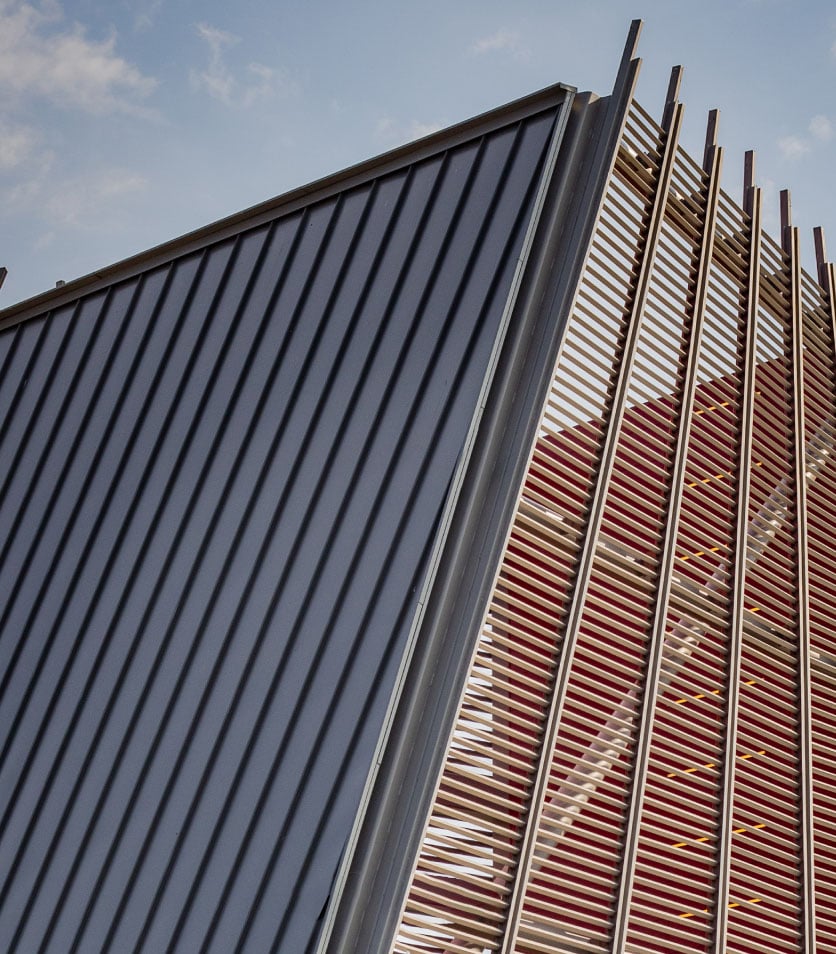

Architectural Facades and Cladding

Walco offers a wide range of cladding and exterior options for commercial projects. A meeting of form and function, cladding is an essential element of any design.

Architectural cladding performs several functions for the exterior of your building. From contributing to an attractive facade to supporting structural integrity to protecting the building from outdoor stressors, these elements are an important component of any building project.

The exterior of a building is always where it makes its first impression. With a range of materials and configurations available, you have more tools than ever to make the impression you want to.

Architectural Facades and Cladding Options

Today there are more options for facades and cladding than ever before. Our offerings combine function with striking aesthetics for anything you want to build.

One of the most prominent features in building exteriors are architectural canopies. Designed to create welcoming, protected entryways for occupants, these features can have a big impact on the way occupants use the building as well as on energy efficiency.

The primary functionality of canopies is to protect occupants from sun and precipitation outside the entryway to a commercial building. This creates greater potential for these outdoor areas to be incorporated into the usable space of a building, and to help entryways stand out visually when they otherwise might be easy to overlook.

Canopies don’t just shade people outside a building. They also greatly reduce the amount of direct sunlight that reaches exterior glass, which can lead to excess heating of the building’s interior. Because of this, canopies can reduce the load on HVAC systems and increase energy efficiency.

Finally, canopies are readily used to distinguish buildings visually, adding color, patterns, or other visual flourishes that can enhance the appeal of a facade.

For light commercial construction, one option that combines thermal performance with a simple, rigid construction is structural insulated sheeting. Consisting of large sandwich panels using a foam core surrounded by engineered wood on the outer layers, this type of sheeting offers numerous advantages.

One of the best reasons to use structural insulated sheeting is its cost-effectiveness combined with quick construction. The large panels are ordered and manufactured to spec, which simplifies the assembly process and lowers onsite labor costs. Structural insulated sheeting is highly energy efficient due to its outstanding thermal performance and construction, which saves costs in the long run, and it uses significantly less raw material than conventional wood, which saves costs up front. Because it uses large panels with few joints, it also promotes indoor air quality by limiting air leakage.

Despite the use of flammable materials in its construction, structural insulated sheeting can be a fire-safe building material. Because it uses a solid core, there’s no chimney effect with this kind of sheeting, which protects in the interior from rapid combustion. The engineered wood layers are treated with a fire resistant coating like gypsum to create a safe, affordable, and effective material for light commercial exteriors.

If you think structural insulated sheeting might be the answer for your next project, reach out for an estimate.

Plank and batten exteriors consist of vertically-arranged planks interspersed with thin, protruding strips of molding called battens. The battens function to protect the seams between planks from weather and other stressors, while giving the exterior a ribbed look. Plank and batten is also a simple construction, consisting of just two alternating pieces.

Plank and batten siding originally came around after the invention of the sawmill, and is still most commonly made of wood. However, synthetic and metal variations are available for commercial construction.

Sometimes called “barn siding,” plank and batten is fantastic for a weather-tight yet rustic look, making it a popular choice for many residential and commercial projects. It’s perfect for property owners who want traditional charm and time-tested durability, and it’s familiar to most any general contractor or builder.

See if architectural planks and battens are the right choice for your building project.

Aluminum composite panelling is a popular and effective cladding solution that prioritizes low average costs, safety, and thermoregulation. The panels consist of a non-aluminum core between two aluminum surface layers, making it a type of sandwich panel. This construction maximizes the benefits of aluminum while reducing overall weight and cost.

This type of panelling owes its popularity to a number of factors.

- Sturdy construction that retains its shape over time.

- Customizable finishes that allow for aesthetic flexibility

- Resistance to deformation from impact or temperature extremes.

- Recyclable

- Simple, affordable assembly and installation

- Lightweight construction

- Fire-resistant construction

The low weight and thermal properties of aluminium composite panelling makes it a great choice for the construction of ventilated facades. By creating an air barrier behind the cladding, the building can take advantage of the chimney effect to keep air moving in an insulative layer around the building. This contributes to lower energy usage and is an essential component of any green building.

Stone is a visually appealing, natural material that looks great on architectural facades. The colors, patterns, and textures in stone form naturally over long periods of time, creating unique pieces and aesthetic qualities that simply can’t be imitated. If you want the look of stone without the weight and expense of masonry, stone cladding is a great option. It’s thinner, much more affordable, and easier to install.

Stone isn’t just beautiful, it’s also extremely durable and easy to maintain. Able to withstand decades of exposure to the elements with minimal care, stone is one of the best long term options for cladding, as well as one of the sturdiest materials used in the construction industry. It’s a great choice for both cladding and load bearing walls.

All that sturdiness comes with the caveat of additional weight. Stone is a very heavy building material, but practices like traditional handset cladding use a backing structure with load-bearing fixings to support the weight of the stone. This creates a highly effective and attractive option for cladding.

Because it is naturally occurring, there are also many different kinds of stone available. From sedimentary stone like limestone to harder metamorphic stones like slate and marble, there are a range of options with different visual and material properties, giving you a great deal of flexibility in what you want to build.

Exterior panels are a common and effective option for architectural cladding. Seen in many different applications from retail buildings to apartment complexes, this form of cladding takes advantage of recent building technologies to create low-cost exteriors that are long-lasting and environmentally conscious.

This type of cladding uses panels, often made of durable fiber cement, hung on a track system that encases the entirety of the building. This method of construction keeps labor and materials costs down by implementing a simple installation system that requires relatively few materials.

The primary function of exterior panels is to keep water out of the building. Using waterproof materials in tight construction isn’t enough, however. That’s why this type of architectural cladding also incorporates an air barrier between the exterior panels and the insulative layer of the structure. This air gap allows any moisture that passes through the panelling to dry quickly.

The air gap also creates natural airflow around the building, which contributes to an energy-efficient design. Combining this with the lowered need for materials and long-lasting nature of the construction, exterior panels are a great choice for any commercial building project.

Roofs and basements often have greater waterproofing requirements compared to other parts of the building. Underground exteriors are exposed to an especially unique set of conditions. One of the most prominent is the threat of groundwater coming in contact with the exterior of the structure. This requires such structures to be adequately protected against their subterranean environments.

Some of the unique stressors in this kind of environment include:

- High water pressure from surrounding groundwater

- Corrosive chemicals in groundwater or soil

- Shifts in pressure from uplift and other processes

- Shocks from seismic activity

Waterproofing membranes are a great choice for basements and other underground structures that must deal with groundwater and hold up in sometimes unstable conditions. Available in PVC-, bitumen-, and TPO- based sheets, waterproofing membranes are easy to apply to concrete masonry and other structural exteriors.

Waterproofing membranes are essential for below ground structures and many other exteriors consisting of concrete construction, as well as some roofing systems. Explore our options to make sure you get the right product for the job.

There’s no way to overstate the importance of keeping moisture out of a building’s exterior layers. Moisture infiltration leads to mold and rot, which compromises the integrity of the building and creates financial pressure in the form of repairs. Readily available in easily-applied rolls of material, air barriers must meet a strictly coded low threshold for air permeance.

An air barrier is an essential component of a building’s defense against moisture. There are a few qualities an effective air barrier must have:

- Meets requirements for air permeance

- Continuous application over the entirety of the building

- A lifespan that matches that of the building

- Durability to resist pressure, temperature, and other factors

Because its function is so important, these qualities are non-negotiable for a building’s air barrier. Fortunately, there are cost-effective, no-headache options for applying an effective air barrier in your next project.

For an air barrier that works with your specifications, get in touch about your next building project.

Metal is a lightweight, sleek-looking choice for cladding that will stand up to the elements and endure for a long time.

Sheet metal cladding comes in various forms. The most common of these is standing seam, characterized by protruding lines between the panels which cover and protect the seams. Snaplock is a simpler version with a similar ribbed look but a simpler installation method. There are also unribbed varieties like interlocking and cassette formations which offer smoother appearances.

Although metal is not a permeable material, metal cladding systems will still make use of a waterproof membrane layer behind the exterior. This layer acts as additional assurance against the intrusion of moisture into the building’s construction. Membranes use a geotextile sheet, sometimes combined with a wire mesh layer, to create a breathable layer that evaporates and protects against moisture.

There are also a variety of metals available for use including aluminum, titanium, zinc, copper, and different kinds of steel. We offer metal and sub metal panel systems for use in your next building project.

Roof Systems and Roof Recovering

Commercial buildings are larger and more complex than residential ones. Because of this, they need larger and often more sophisticated roof systems. There are a number of options for creating or restoring a roof system for your commercial building project. Here at Walco, we can design the perfect roof system that is tailored to your needs, while keeping supply chain challenges in mind.

Whatever obstacles you face, you should be able to take advantage of one of the different kinds of roof systems available. From solid metal roofing to liquid applied roofing, there’s a way to work around any set of circumstances to build an attractive, energy efficient, and watertight roofing system.

Flat Roofing and Roof Recovering Product Descriptions

Our options for roof systems and roof recovering give you the tools to get results no matter what your situation calls for.

Metal roofing has grown in popularity in recent years due to its unique advantages and industrial style appeal. Its long lifespan compared to many other materials means it can look great well past the first decades of a building’s life without need for replacement.

A terrific choice in warm climates, metal’s reflective nature deflects solar radiation and keeps interiors cool, easing the load on HVAC systems and reducing energy costs. In addition to this, metal roofs are often made with recycled materials, and are themselves recyclable, making them even more of an environmentally conscious choice.

Another reason to choose metal roofing is its durability and resistance to several kinds of hazards. Like a suit of armor, metal roofing is highly resistant to fire, precipitation, and all but the most punishing winds. It’s even impervious to biotic buildup like fungus and moss that can degrade the quality of other roofing materials.

If you want highly-durable, attractive, and energy-efficient roofing, metal may be the best choice for your next project.

Commercial buildings frequently use roofs that appear flat, but in actuality are pitched very low. Roof pitch is expressed as a ratio of vertical inches to horizontal inches, such as 3/12, which refers to a roof that rises three inches for every twelve inches it extends. 3/12, it just so happens, is also the maximum slope for a low slope roofing system.

Low slope roofs offer two primary advantages to property owners: low cost and HVAC placement. Roofs that are pitched low or nearly flat cover more building surface with less roofing, cutting down on material costs. They also provide space for HVAC equipment like air conditioners to be installed where they are safe from theft and vandalism, easily accessed by maintenance personnel, and can take advantage of gravity to more easily transfer cool air into the building directly below.

Because these kinds of roofs are pitched low, they cannot be covered in shingling like many residential roofs. At a very low pitch, a roof does not reliably shed water, and so it must either be completely covered with a waterproof membrane or made of a waterproof material like metal.

There are a number of low slope roofing options available for your commercial building project.

Liquid applied roofing solutions come in the form of fluid-based coatings that are applied across the solid substrate of a roof. These solutions can be applied across transitional, damaged, or otherwise vulnerable areas to create a waterproof coating. When the liquid applied solution cures, it will form a tough yet flexible coating without seams or gaps.

Ideal for roof recovering, liquid applied roofing solutions are an adaptable and easy way to preserve and extend the life of an aging roof system. The conformability of the fluid allows you to work around existing structure and problem areas that solid roofing materials may not be able to handle, and without wasting material.

Some advantages of liquid applied roofing include:

- Seamless application for maximum protection

- Reliable, long-term waterproofing

- Easy, uncomplicated liquid application

- Eliminates the need to repair or replace aging roofing systems

- Can increase UV reflectivity and lower energy costs

Whether you need to restore an existing roofing system, or build a new one that is inexpensive and made to last, liquid applied roofing solutions may be the option for you.

A relatively recent material to be developed, modified bitumen is an improvement on earlier asphalt-based roofing materials. Reaching widespread use in America in the mid-seventies, modified bitumen consists of asphalt that has been modified with polymerized rubber or plastic and reinforced with fiberglass. This marvel of engineering offers enhanced durability and protection over earlier asphalt-based materials.

Modified bitumen offers several advantages:

- Tough, tear-resistant material

- Waterproof protection

- Easy installation and repair

- Flexible, temperature-resistant material

- Reflects heat and UV radiation

That’s plenty of reasons to use this proven material. Readily available in rolls that are applied directly over the roof’s substrate, modified bitumen can be applied with heat-welding or cold adhesive, in two or more layers depending on the project needs.

Modified bitumen is a fantastic choice for all kinds of commercial roofing. Get in touch so we can find out if it’s right for your project.

"I have known about Walco and they have worked with me for over 30 years. I have always considered them the go-to company when I needed information or help with any of their products. I’ve received same or next day in person delivery of product data, samples, technical information and if that was not available, advice on other or similar products that might solve my problem, not to mention contact data for manufacturer’s reps. It’s always where I start."

Dwight Rosenbaum

FSB

What You Need to Know to Get Started

There are a lot of moving parts with any construction project. Let us provide any answers you need ahead of time.

Can you help me spec my project?

Yes, we can help provide or write specifications for your project and supporting documentation to go along with performance qualifications

Do you install or manage any of your product offerings?

We do not install any of our products. We do have great relationships with local contractors who can help with your installation.

Do you do nationwide distribution?

We offer nationwide distribution for our architectural and structural skylights. Distribution for our other exterior construction products is limited to Oklahoma and Arkansas.

What’s the difference between low slope and no slope roofing?

Low slope roofs are roofs that rise three inches or less for every twelve inches they extend horizontally. This means that the roof has a pitch of 3/12 or less. While no roof should be perfectly flat, a “flat” roof is one that is below this threshold and appears flat to the eye.

What’s the difference in a TPO vs PVC roofing membrane?

TPO and PVC are both thermoplastics, but are based on different chemical compounds. TPO consists of ethylene or polyethylene thermoplastic combined with ethylene propylene rubber. PVC, on the other hand, consists of polymerized vinyl chloride monomers with additional agents added to increase flexibility.

The less technical answer is that they are very similar, but TPO is cheaper and more environmentally friendly while PVC is somewhat tougher and easier to install.

What is the stronger skylight: acrylic vs polycarbonate?

Polycarbonate is 20 to 30 percent stronger than acrylic and can withstand a hailstorm. These performance improvements far outweigh the slight difference in price over acrylic.

What’s the best architectural facade for my building?

Every building project is unique, and there are more options for architectural facades than ever before. The best option is to contact us so we can assist in choosing the right facade for what you’re working on.

Read More About What We Do

Let’s Start Building

We’re here to help with your next project. Get in touch today.